By 2010 Danaher had become a family of strategic growth platforms. Over 50 acquisitions between 2001 and 2006 allowed Danaher to transition from a cyclical industrial company to a scientific and technical instrumentation company. Danaher gained control of five growth platforms along with operations in seven focused niche businesses.

The Danaher Business System (DBS) was, and still is, the central pillar of the company’s growth strategy. This system sets the guideline for planning, deployment and implementation of the strategy, under the KAIZEN™ – continuous improvement -principles. Lary Culp, CEO of Danaher Corporation in 2010, wrote on the shareholder annual report “DBS tools give all of our operating executives the means with which to strive for world-class quality, delivery, and cost benchmarks and deliver superior customer satisfaction and profitable growth.

The successful implementation of the DBS system across acquired businesses resulted in their rapid growth. Operational margins grew at an impressive rate along with the number of new product introductions to the original portfolio.

The successful implementation of the DBS system across acquired businesses resulted in their rapid growth. Operational margins grew at an impressive rate along with the number of new product introductions to the original portfolio.

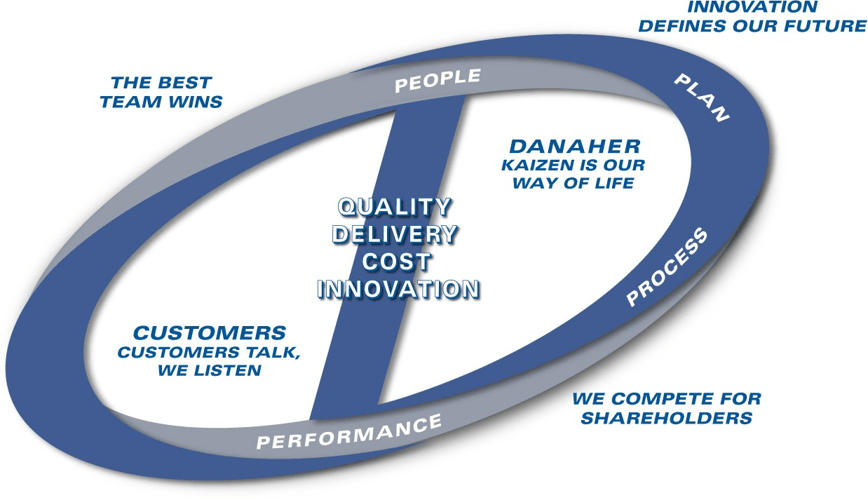

Danaher Business System

Danaher took its first steps with KAIZEN™ methodologies in 1988 by implementing Toyota’s Lean manufacturing, with great success. From 1986 to 2000, Danaher grew from 16 operating companies to 51 operating comanies. 86% of the revenue from tires and rubber goods turned into Environmental, Electronic Test and Motion Control platforms. Along with all the business tranformation, what started as an implementation of Lean manufacturing, evolved into a KAIZEN™ system encompassing continuous quality improvement tools and principles. The DBS came to be recognised as the keystone of the firm’s continual success.

The DBS applies the Lean approach to replace the tradicional “batch-and-queue” manufacturing system with a “single-piece flow” that minimises inprocess time and reduces inventory and other overhead costs. These principles were taken to transactional processes as well, expanding the system to focus on innovation, growth, marketing and sales. New tools such as Accelerated Produc Development, Strategic Pricing and Intellectual Property Management guarantee that the challenge of accelerated growth is tackled with the same KAIZEN™ mindset that is used in cost and efficiency challenges.

The DBS approach is supported by four principles: People, Plan, Process and Performance. The application of these principles in current or new businesses is made with an emphasis in Growth, Lean and Leadership. People: talent assessments are carried out during reviews of the current business or as part of the acquisition due diligence, to identify those who might not fit the Danaher culture. Plan: To answer the questions “What game are we playing” and “how do we win”, a strategic plan is created for every business. This plan should encourage managers to acknowledge their improvement opportunities and produce a shared long-term success vision. Process: the immersion of managers into DBS processes starts with a week training session and closes with a one week KAIZEN™ event. The goal is to deep dive into KAIZEN™ concepts such as single piece flow, visual maps and benefits tracking. Performance: a policiy deployment tool is put to action in order to drive and monitor the strategy implementation.

Strategy Deployment

Danaher used to make three-year strategic plans every year, through the application of a systematic process, like the Balanced Scorecard. This was a heavy process that resulted in a number of complex documents that were kept confidential. This secrecy made it difficult to execute the strategic plan, as teams had little to no knowledge of its purpose and initiatives. Initiatives took a long time and most of them failed to achieve the targets. A countermeasure process was far from being in place and gaps to targets were not being addressed.

Danaher decided to accept the challenge to implement an effective Strategy Deployment System.

The first key event to implement the New Strategy Process is the VSA: Value Stream Analysis in Operations. It is a team-building eye-opening exercise, with the top managers split into groups, to do a value-stream map and acknowledge the improvement opportunities in their supply chain. These improvements may contribute to reduce inprocess time, increase service level or reduce defects rate.

The next major event is the Strat Plan. Through the Strat Plan discussions, it became clear that Danaher probably knew their own existing customers very well, but they did not know their competitors’ customers. Once they realised this, they also saw that they didn’t have a growth strategy because their market focus was not clear. The output of the Strat Plan is a list of five to seven strategic priorities to be achieved in the mid-term.

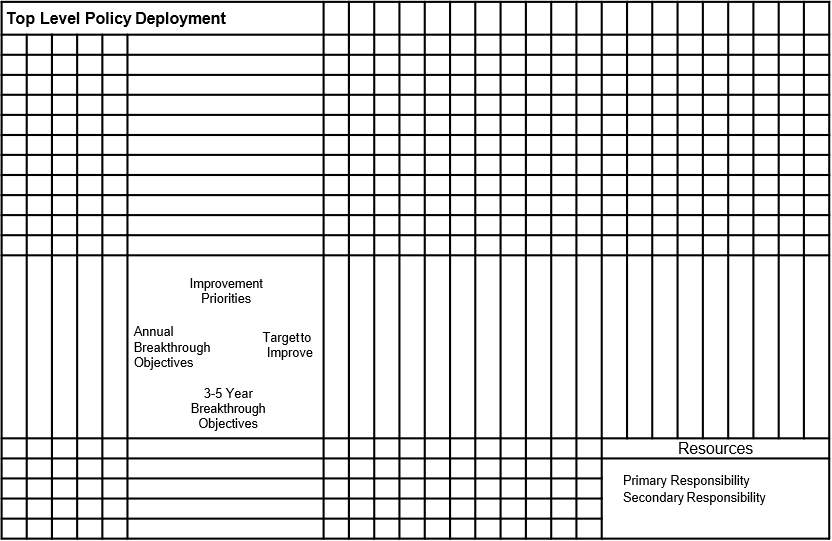

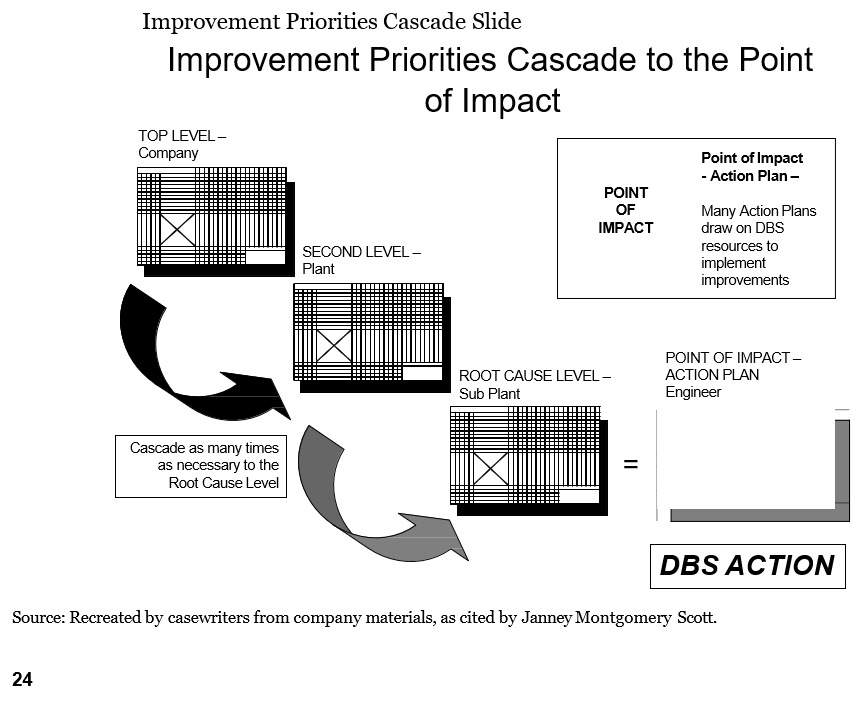

To improve the execution of the Strat Plan comes the Policy Deployment or Hoshin Kanri. The strategic priorities are broken down into a series of one year goals. This is followed by the identification of the processes that need to change along with the metrics to effectively monitor their improvement progress. The level one goals are translated into level two goals for each department and then into individual action plans. The key to the success of the execution comes with the Policy Deployment meetings where the gap to the target is identified and root causes and countermeasures were defined.

Top-Level Policy Deployment Chart

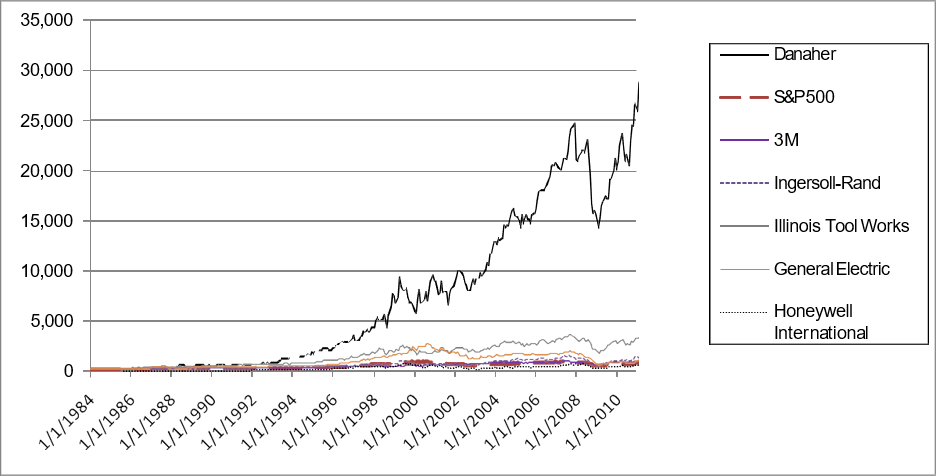

The Results

Due to the DBS Culture and the Strat to Action Process, Danaher has grown profitably by almost 30% every year. This is also reflected in market valuation: 80.000% growth since the 1980s.The generation of extremely high Free Cash Flows allowed the company to implement a very successful M&A Strategy with a strong effect in TSR Total Shareholder Returns. The evolution of KAIZEN™ from the manufacturing floor and the back office to innovation, marketing, R&D and sales allowed for a cumulative return on Danaher’s stock from 2001–2010 over 150%, in comparison with S&P 500 returns of about 25%.

Danaher Share Price versus S&P and Competitors, 1984–2010 (indexed to 100)

Based on Harvard Business School “Danaher Corporation” by Bharat N. Anand, David J. Collis, Sophie Hood

#strategy and leadership #culture and organisation

See more on Strategy & Leadership

Find out more about improving this business area