Demand volatility is a growing reality in our rapidly changing economy. This is a result of technological evolutions in the development of new products, as well as the increasing demand for customisation by consumers. Manufacturers experience the impact caused by demand variation in terms of productivity. In this context, it is important to correctly manage the capacity of production lines in order to achieve the desired output levels. As volatility increases, the task of managing this variability becomes ever more complex, yet critical for production efficiency.

The adoption of traditional methodologies developed for repetitive industrial environments does not produce the optimal model for managing production schedules, since these methodologies do not incorporate the variation in capacity or type of product to be manufactured.

What are the obstacles for production flexibility?

Many organisations mistakenly look to high investment within industrial facilities as the first stage for achieving flexible production capability. Several implementation cases show that the first stage should always be to engage and work with the teams operating in the production environment.

The variability in performance standards between individuals within production teams typically emerge as the first determining factor limiting flexibility. The need for clarity in understanding of task execution methods and sequencing of operations is key for the team to be able to work in different workplace layouts.

When new team members are introduced to a production facility, they are typically allocated to work on a specific task at a fixed workstation. This results in individual specialisations of operator and simultaneously a limited work routine. The approach does not encourage workers to acquire new skills, limiting their capability to execute a wider variety of tasks.

Specialisation of operators solves short-term issues with productivity, however there are many risks associated with this approach. The concentration of knowledge with individual operators results in a risk for the business if one of these employees leaves their role. The force of habit and repetition are also demoralising for workers, who feel the intrinsic resistance to change when it is necessary to adapt their working routines.

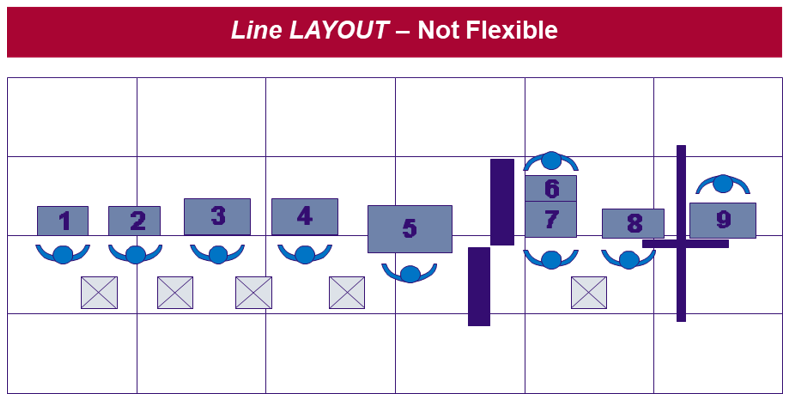

To achieve production flexibility, organisations need to build flexible teams with a wider coverage of skills. This enables teams to adapt to changing production requirements, regardless of the tasks involved. The physical workspace must also offer flexibility, allowing for rapid layout changes and product combinations as a response to the increasing variability in customer demand. It is common to find rigid production lines consisting of isolated island, or lines which occupy a vast area and do not allow for rapid changes in terms of product mix or workstation layout.

Performing Utopia – Shojinka

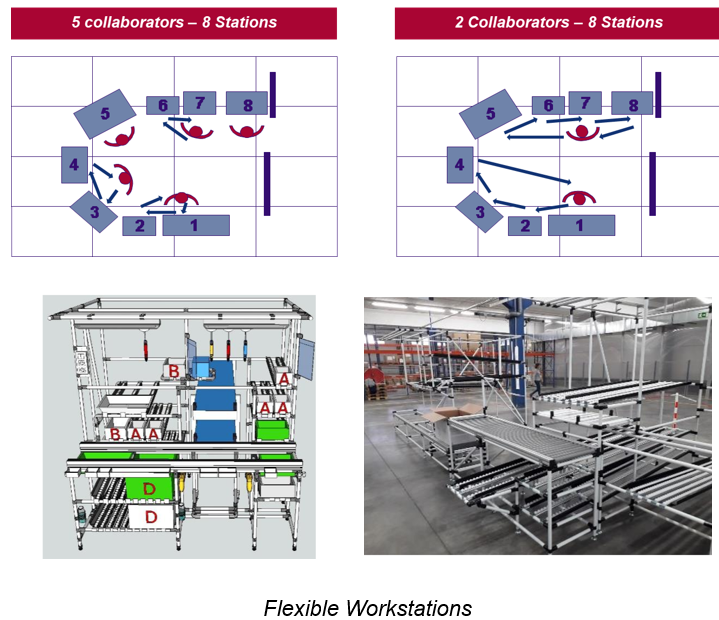

Industries looking to adapt their practices to manage market volatility in demand should look to implement a Shojinka model. Shojinka is a Japanese work meaning flexible production and it refers to an agile production model which can be adapted in response to demand fluctuations. The agility comes from the quick reallocation of resources considering the volume and type of demand, ensuring high levels of productivity and quality. The successful implementation of such models requires the obstacle of flexible work teams to be achieved in advance.

How to Promote Worker Flexibility and Eliminate Variability?

The culture of an organisation plays a pivotal role in the motivation of employees to learn new roles. A management model which factors in operator task rotation, aligned with training and development plans for each individual, will reduce the risk of losing the organisations expertise and increase team motivation (as it increases the motivation levels for each individual). Operator task rotation also prevents repetitive strain injuries over long periods of time, which has positive effects such as reducing issues related to absenteeism.

The first stage to achieving a flexible work team is to map the skills of each individual employee and plan the necessary training to avoid any skills gaps. Simple, visual work standards are critical to support training and accomplish task completion in line with the most effective methods. This reduces product variability through better standardisation and task execution, regardless of which individual is performing the task. The implementation of low-cost automation solutions, such as the use of gravity rollers to reduce operator movements and improve ergonomics, simplify the tasks and facilitate learning.

How to Create Flexible Layouts?

The “U” shape layout typically enables the greatest flexibility in operator task execution. The communication between workers and the proximity to colleagues help manage line efficiency through collaboration between operators when compared to traditional “island” workstations or in-line layouts. Logistical operations are also simplified with the “U” shape layout, due to the inbound and outbound materials transferring from the work area at the same location. The logistical tasks must be considered when designing the work area, as they too must be capable of adapting to fluctuations in demand. Flexible logistic operations are critical to ensure that there is no excess material or disruption to the production cells.

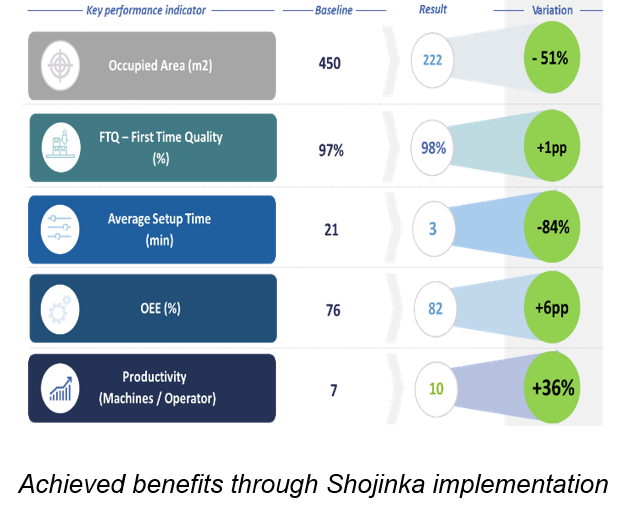

The transition to the Shojinka model increases productivity, quality and customer service levels, whilst reducing infrastructure costs. Many organisations have been able to implement these solutions, with breakthrough impacts seen clearly in the company’s results.

Agility in production implies having flexible teams and easy-to-adapt workplace infrastructures. The implementation of the Shojinka principle maintains high efficiency in production lines, regardless of the demand fluctuations. In current markets, achieving such flexibility translates into a direct competitive advantage that could prove to be the key for organisations to adapt to the uncertainty in consumption we see in our increasingly changing economies.

#assembly manufacturing #operations

See more on Assembly Manufacturing

Find out more about transformation in this sector

See more on Operations

Find out more about improving this business area