Enterprise Value Stream Analysis

It is important to visualize all activities performed in the organization to identify waste in the product or service. This is performed by mapping every task from phase one to delivery. This is a KAIZEN™ Event called Enterprise Value Stream Analysis.

When a flow is interrupted, we know that we are not adding value but generating waste. It is essential that everyone in the organization understands which activities add value and which do not – in the eyes of the customer. Only then does the full extent of the waste become visible.

Once the current state has been mapped and the data confirmed, the team can design the future state that has removed substantial amounts of waste with the necessary action plans to deliver the results. The KAIZEN™ Enterprise Analysis analyses the entire organization through an 11-step process that leads to the design of a Breakthrough Vision for the future.

In world-class manufacturing organizations, 300 minutes are needed to add 1 minute of added value, but the average company is closer to 10,000 minutes.

Define value

Define added value by understanding what the customer wants. Use gemba to observe and measure activities, including tasks, times, and inventory, to capture real data.

Map material flow

‘Current state’ mapping is used to identify all steps in the current process, highlighting potential flow interruptions of what is happening in practice.

Map information flow

Map lines of communication and information shared between departments, from customer to service. Link planning to physical work by triggering the correct sequence of work, and identifying handovers.

Add data to process steps

Add data to each process step to show the organization’s ability to deliver on time, manage resources, and locate potential productivity gains and decreases in flexibility (non-value-added activity).

Devise the vision

Ensure the teams design innovative solutions that include only what is necessary to produce excellent quality, low cost and high-delivery performance by implementing simple, practical fixes.

Identify value streams

Have teams look at simpler, more efficient ways to flow materials and information to simplify flow and reduce Lead Time to provide greater flexibility and build an extended vision of the ideal value stream.

Choosing groups

ABC Analysis is the most effective tool for improving quality, cost and delivery. Separating high volume low variety with low volume high variety with runners, repeaters and strangers will maximize value stream design.

Change paradigms

Identify, visualize and break down the paradigms disrupting your ideal vision. Change your way of thinking by encouraging your teams to challenge the status quo and build their knowledge base.

The ideal state

The ideal state has zero waste and no constraints as well as perfect flow, world-class quality, low cost and on-time delivery. This shift in thinking allows for design and concept principles in the current state.

The future state

Decide what you want to achieve in the next 6-12 months. Waste remains in the future state so deliver cycles of value stream mapping to create a world-class process and a continuous effort to eliminate it.

Track benefits

Calculate potential gains from the future state implementation by monitoring KPIs. The KAIZEN™ Enterprise Analysis helps prepare Hoshin Planning. Through this process you will realize the strategy and breakthrough objectives of the future.

Department Value Stream Analysis

To deliver a more effective improvement deployment program, there is a need to perform a detailed analysis of the processes involved, including opportunities for breakthroughs, optimization and acceleration. This is a crucial stage in Hoshin Planning as it forces leaders and their teams to think that breakthrough objectives will only be achieved when sub-processes are really improved.

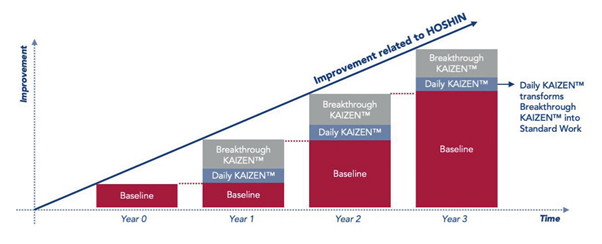

“Strat to Action” is the implementation of two improvement processes – Breakthrough KAIZEN™ and Daily KAIZEN™. The former develops breakthrough objectives allowing the organization to step change performance, but these results are only sustained if a Daily KAIZEN™ program is implemented, which converts the new way of working into standardized work.

Long-term sustainability is guaranteed by making Daily KAIZEN™ a reinforced systematic and regular training and follow-up program, creating employee habits.

The following chart shows how Hoshin can support the implementation of these two KAIZEN™ approaches. The results achieved year after year are multiplied until the strategic objectives are reached.

Many organizations apply continuous improvement, Lean or operational excellence tools in a random way, rarely seeing their impact on financial performance as tools get lost in the noise of the organization.

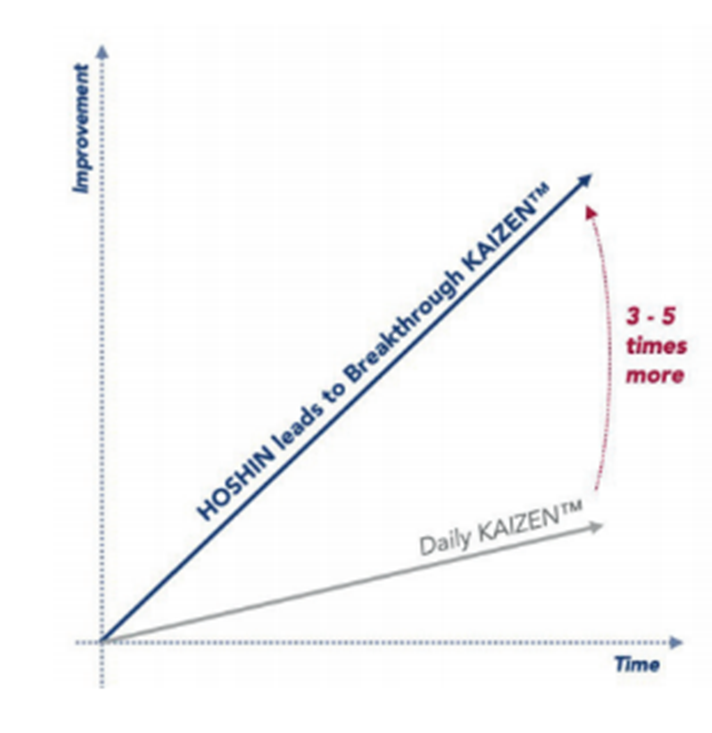

It is very important that you use Breakthrough KAIZEN™ together with Daily KAIZEN™ to keep multiplying the results 3 to 5 times compared to the traditional approach to improvement. Managers must learn to see waste in their organization and how aggressive they should be in defining improvement goals.

#improvement projects #strategy and leadership

See more on Strategy & Leadership

Find out more about improving this business area