The Challenge

Problem

• Summer shutdown maintenance with many inefficiencies and a lack of standards

• High manpower costs (80 external resources)

• Long duration (3 weeks)

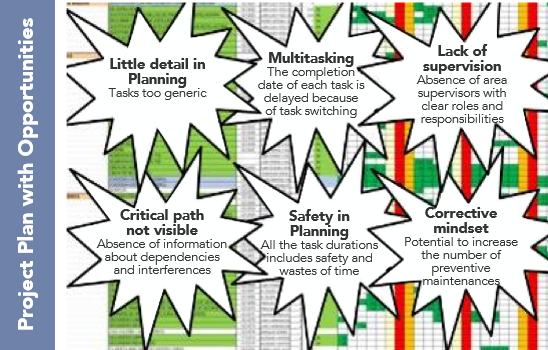

Root Causes

• Spares/tools not ordered in advance

• Critical Plan not visible

• Tasks planned with a lot of safety (buffer)

• Little time invested in task and resource planning

The solution

• Pull Planning with Time and Cost Buffers

• Visual Management Boards for work and KPI monitoring

• Spare parts stored near machines, and tool/consumable kits prepared

• Daily cost control

The Results

The project resulted in Annual Savings of £2.5 million.

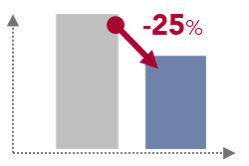

Manpower cost reduction

Manpower costs reduced by 25%

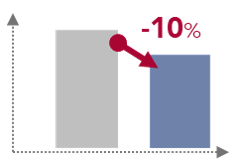

Shutdown duration

Shutdown duration reduced by 10%

#process manufacturing #research and development #maintenance

See more on Process Manufacturing

Find out more about transformation in this sector

See more on Maintenance

Find out more about improving this business area