The Challenge

Problem

• Low productivity amongst maintenance teams

• Lengthy stoppage times due to excessive MTTR (Mean Time To Repair)

• Complete dependence on maintenance teams to solve every equipment issue

Root Causes

• Poor knowledge sharing between production and maintenance teams

• Interventions on the equipment done with an isolated approach, with no standard or historical information

• High volume of corrective interventions over planned interventions

The Solution

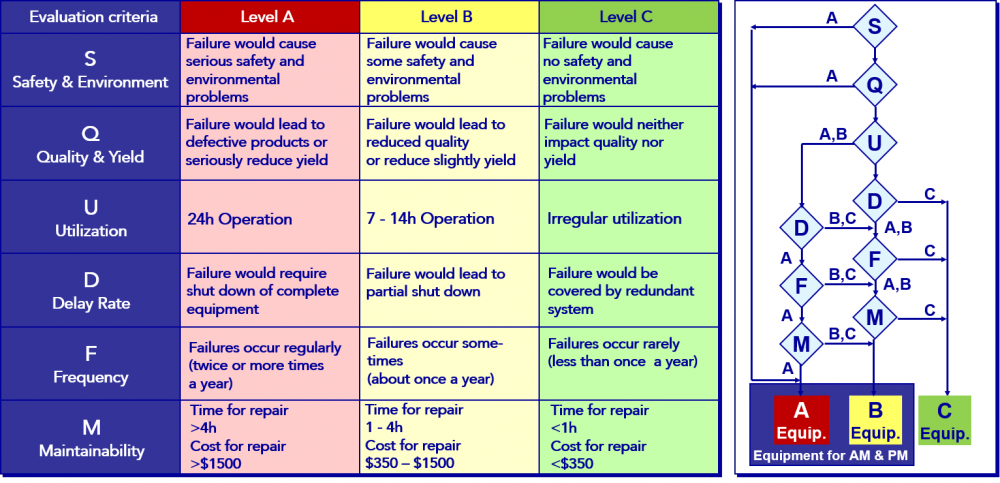

• Equipment classification according to their criticality: risk of employee injury, equipment without replacement, unstable OEE and high percentage of breakdowns

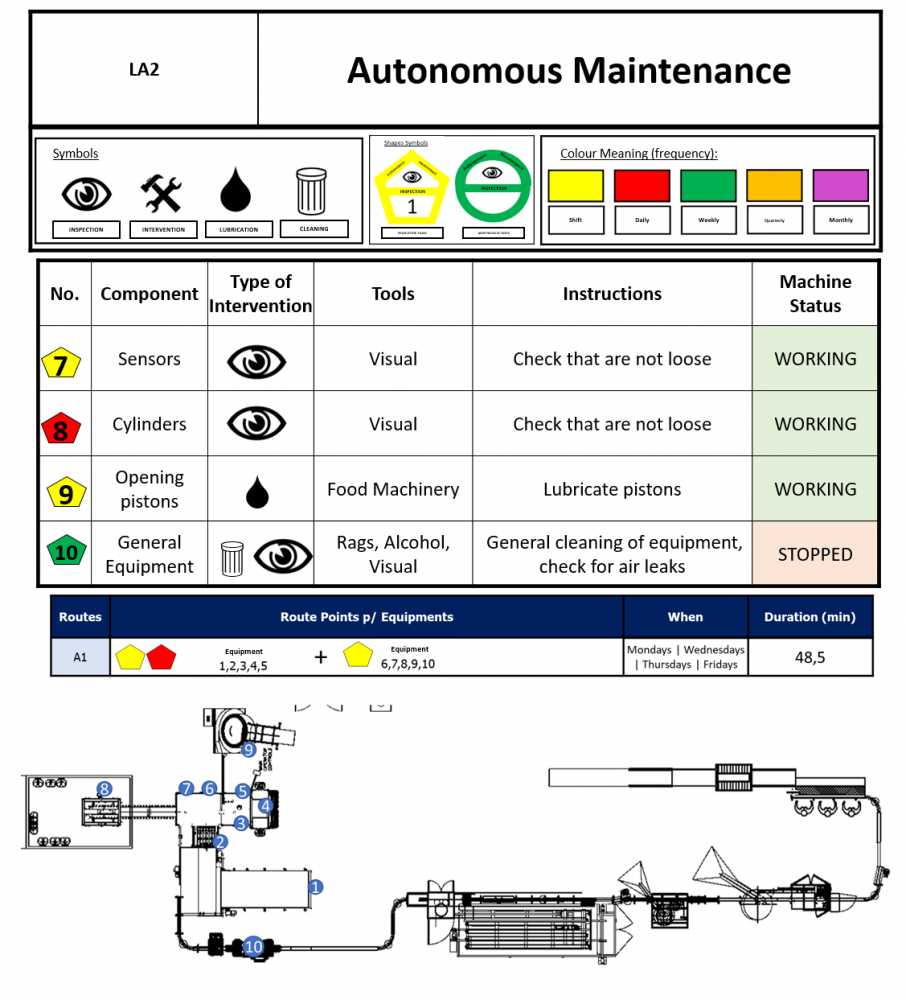

• Implementation of Autonomous Maintenance processes on the critical equipment, with a standardized process to train all team members and assess their knowledge

• Development of a planned maintenance schedule, where the high-frequency activities were passed on to autonomous maintenance

• Work instructions development for planned maintenance activities, with a yearly training calendar for the maintenance team

The Results

The organization was able to free more than £479,000 in cashflow.

Stock Value

The stock value of spare parts was reduced by 26%

#assembly manufacturing #process manufacturing #maintenance

See more on Process Manufacturing

Find out more about transformation in this sector

See more on Maintenance

Find out more about improving this business area