The Challenge

Problem

• Low productivity of production and logistics teams

• 50 000m2 of extra rented warehouse space

• Necessary to adjust capacity in order to absorb new models to be produced

Root Causes

• Unbalanced combination of references to be produced on each production line

• Poor usage of available space, with inefficient layouts and structures

• Complex flows for movement of information and materials internally

• Packaging of material not adapted to specific product characteristics

The solution

• Project management using Mission Control Room, KAIZEN™ Events and Task Force Initiatives

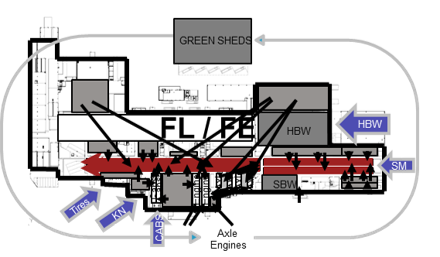

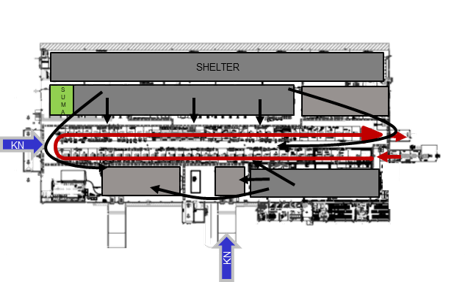

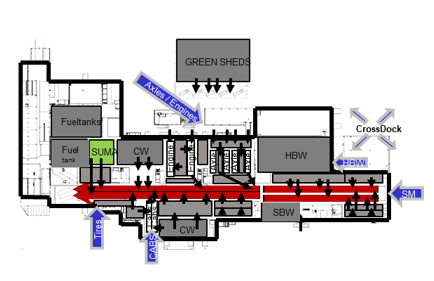

• Layout organised according to fishbone concept: Line – Pre-Assembly – Kitting – Warehouse – Receiving Gate

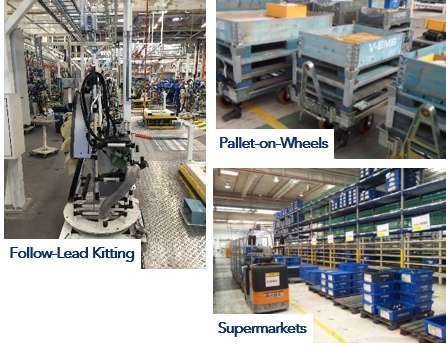

• Follow-Lead Kitting, Pick-to-Light and Guided Trolley

• Implementation of Pallet-on-Wheels, Mizusumashi principle and Manual Transports

The Results

The project had a Payback period of 8 months with annual savings surpassing £38 million.

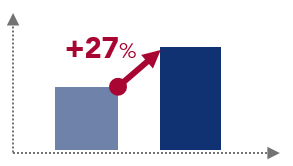

Production Productivity

Production productivity increased by 27%, through the elimination of non-value-added activities

Amount of warehouse space required reduced by 30%

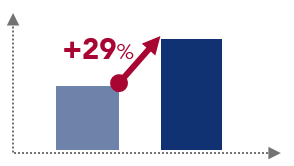

Logistics Productivity

Logistics productivity increased by 29%, through the optimisation of layout and containers

Warehouse team productivity increased by 8%

#assembly manufacturing #operations

See more on Assembly Manufacturing

Find out more about transformation in this sector

See more on Operations

Find out more about improving this business area