The Challenge

Problem

• High industrialisation costs of new products

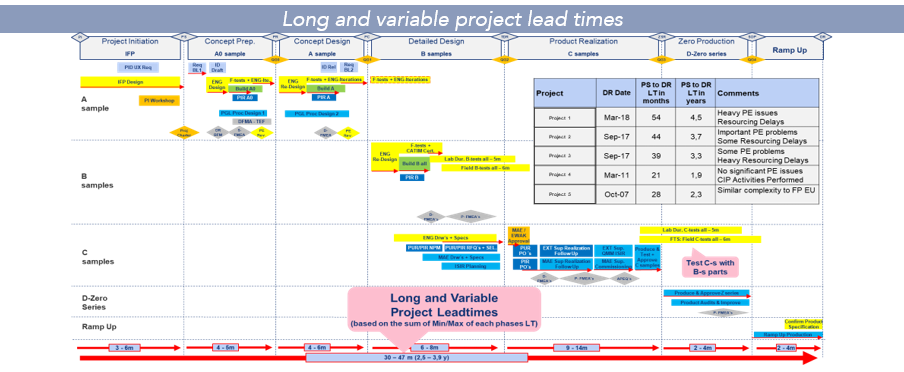

• Projects with long and variable Lead Times

• Engineering teams involved in firefighting to solve problems and delays

Root Causes

• Focus on developing a prototypes to test, without validating feasibility or customer requirements beforehand

• Initial stages of conceptualisation and design were not adequately validated in line with customer requirements or the business directives

• Product quality problems causing rework and delays in the industrialisation stage

The solution

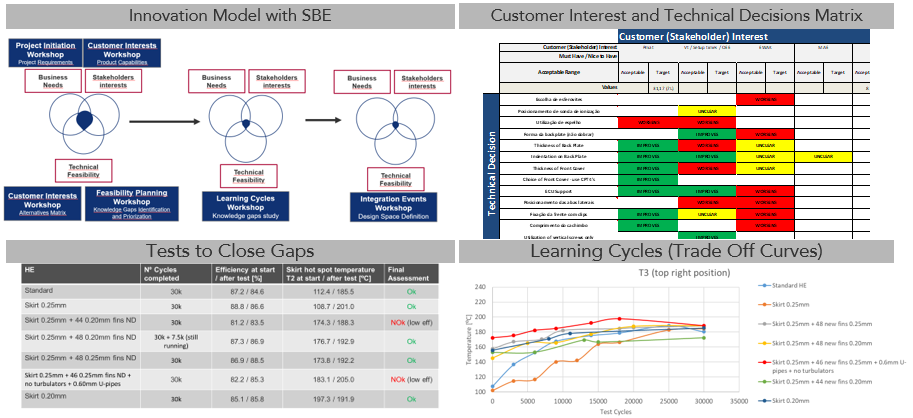

• Innovation model design with Set Based Engineering (SBE) and design sprint cycles

• Customer insights analysis to identify product use cases

• Knowledge gap prioritisation based on feasibility planning

• Learning cycles with trade-off curves for knowledge reuse

• Integration events creation to define the optimal solution based on the learning from the tests

The Results

The project generated benefits of £2.3M

Project Lead Time

Project Lead Time decreased by 49%

Industrialisation Rework

Industrialization rework lowered by 30%

#assembly manufacturing #process manufacturing #research and development

See more on Assembly Manufacturing

Find out more about transformation in this sector

See more on Research & Development

Find out more about improving this business area