Challenge

Problems

• Company used to improving results with CAPEX investment

• Dense and highly complex organisational structure

Root causes

• Continuous Improvement Culture neglected in terms of investments

• Numerous simultaneous projects in progress, with several departments involved

• Lack of focus and method for identifying opportunities in the workplace

• Non-standard Project Management, with ad-hoc meetings and weak Visual Management

The solution

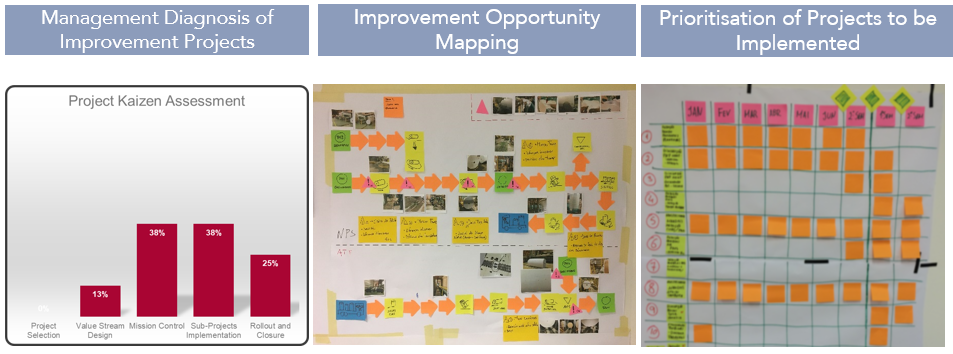

• Value Stream Analysis to identify and prioritise necessary projects

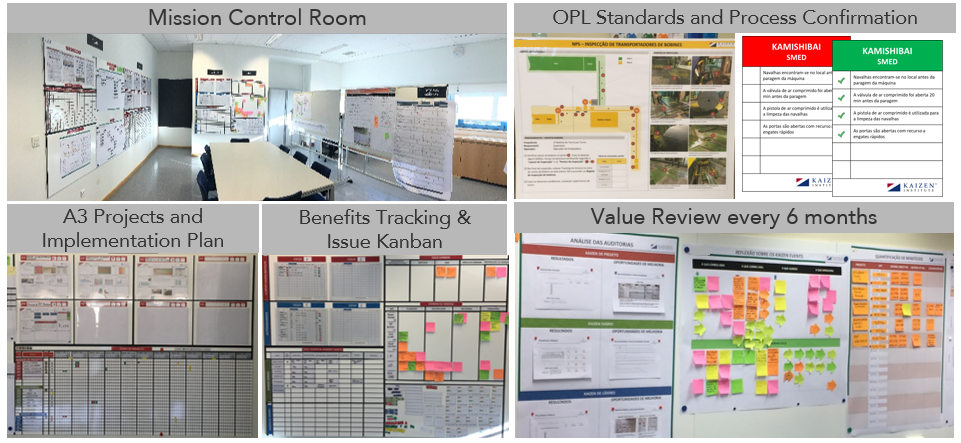

• Mission Control Room (Obeya) for Project Management and Steering Committee

• KAIZEN™ Events workshop, following the A3 Thinking methodology

• Stabilisation Process of Improvements using Standardisation and Process Confirmation with Kamishibai

• Value Review process every 6 months and planning of the next cycle

The Results

This project generated £3.2m/year

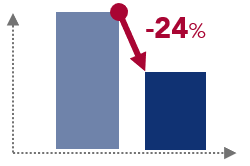

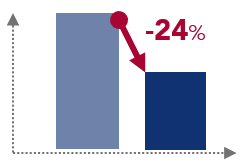

Planned stoppages

Planned stoppages reduced by 24%.

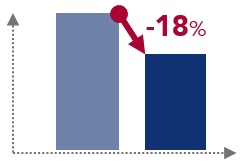

Unplanned stoppages

Unplanned stoppages reduced by 18%

Energy consumption

Energy consumption reduced by 24%

#process manufacturing #improvement projects

See more on Process Manufacturing

Find out more about transformation in this sector

See more on Improvement Projects

Find out more about improving this business area