Maintenance is one of the most significant business areas in an industrial company, with a direct impact on all stages of the production process. Industries tend to invest in high-quality equipment and machinery with a long-life cycle which must be managed and preserved effectively. Efficient maintenance ensures the continuous flow of the production process, allowing excellent operational results to be obtained in the form of cost reduction and increased productivity.

Considering that maintenance costs represent on average, 15 to 40% of the operational costs and planned stoppages result in a 5-10% loss in equipment efficiency, it is necessary to apply a model with the clear objective of reducing these and other relevant indicators like Mean Time Between Failures (MTBF), Mean Time to Repair (MTTR) and Overall Equipment Effectiveness (OEE). The implementation of Total Productive Maintenance (TPM) has resulted in successful cases in several industries, proving to be the approach that addresses all variables that affect equipment performance.

TPM is an approach based on a balance between planned and autonomous maintenance interventions with the objective of achieving an ideal production environment, seeking to maximize efficiency, based on a strong alignment between the operational teams – production and maintenance.

Dealing with unplanned downtime should be seen as a priority for organizations. In the automotive industry, each stop costs about $1.3 million per hour, which is represented by lost production time and, consequently, lost sales.

Despite the significant impact of downtime, 70% of companies still don’t have visibility into when their equipment should be stopped and intervened to avoid unplanned stops.

Only 26% have adopted a predictive maintenance strategy based on data and algorithms that make it possible to identify the optimal moments for equipment maintenance with greater precision.

Efficient maintenance teams are prepared to solve the challenges that arise. Still, they must also have the ability to anticipate future challenges by finding the right balance between working on resolving malfunctions – corrective maintenance – and preventing them – preventive maintenance. An efficient strategy to optimize the performance of maintenance teams is to evolve the TPM model in order to reduce the need to perform reactive maintenance while giving priority to predictive maintenance.

What are the three main maintenance strategies (reactive – preventive – predictive)

Reactive maintenance was the most common approach over a long period of time in different sectors of the economy. In a general way, it is about solving problems after failures occur. Following this approach, maintenance teams only act when called upon, and the stock of spare parts is small, only replenished with ad-hoc purchases.

When the organization opts for a reactive maintenance strategy, unexpected breakdowns force equipment downtime, reducing the availability of machines. Unplanned downtime can result in idle employees, production line stoppages, missed deadlines or late deliveries, the need to incur overtime, and energy overconsumption.

The occurrence of a failure in a single component can also compromise the condition of numerous other components inside the machine, increasing the time needed to repair them and leading to downtime costs for the organization and its repercussions.

While reactive maintenance is an approach to resolve failures and reset conditions to operate correctly, preventive maintenance seeks to prevent failures from happening, relying on a periodicity to check the need for maintenance or to effectively perform maintenance tasks on equipment.

Preventive maintenance is, in its definition, the set of activities carried out regularly (according to a planned schedule) to maintain equipment’s conditions and operational status.

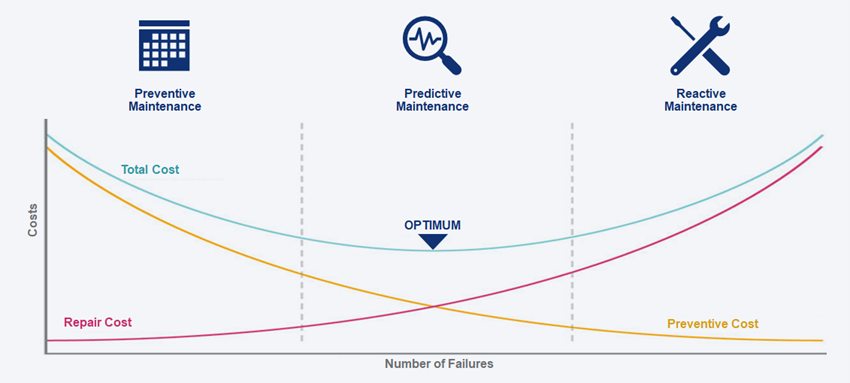

Predictive maintenance has the main objective of formulating a forecast based on data and algorithms to find out, with high precision, when equipment maintenance is needed. The implementation of this approach consists of constantly monitoring the conditions of the equipment throughout its normal operating process to predict and detect potential problems and correct them promptly before they result in failures. It seeks to respond to two significant problems associated with organizational maintenance models:

- The high costs associated with excessive periodic maintenance – are often unnecessary.

- The high costs associated with an unplanned stoppage – which is often avoidable.

Predictive maintenance differs from preventive maintenance in that it is based on the actual condition of equipment and not on average or expected life statistics. This methodology tries to detect failure patterns and anomalies, learn from them, and then predict future failures of machine components so that they can be replaced before they fail.

The ‘predictive’ component of predictive maintenance stems from the goal of predicting the future trend of the equipment’s condition and it uses principles of statistical process control to determine at what point in the future maintenance activities will be appropriate.

In this strategy, repairs occur whenever the analysis of the equipment’s condition makes it foreseeable. Maintenance teams work on-call and have well-structured routines for lubrication, replacement of worn parts, inspection/measurement, and statistical analysis of performance. Spare parts stock management is based on anticipation based on the condition and/or forecast of a possible failure.

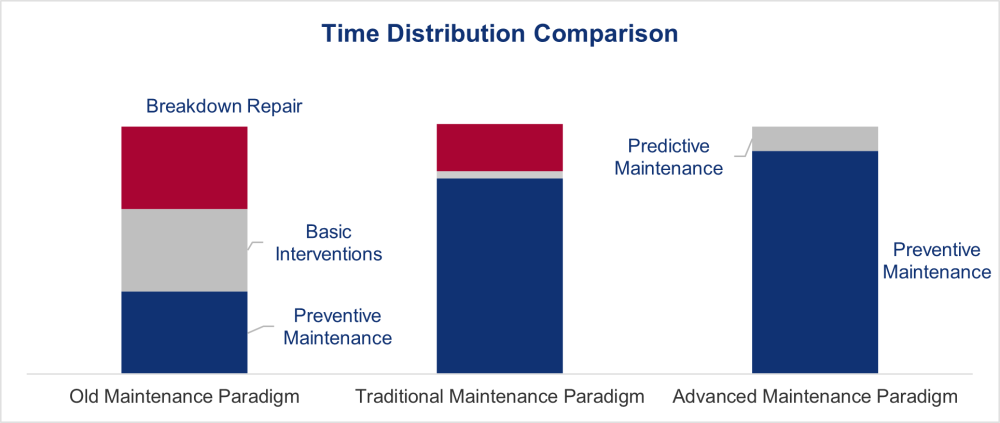

The image below shows the time distribution with comparisons between different maintenance approaches.

The goal and potential impact of predictive maintenance

Predictive maintenance should be implemented in equipment that has a critical operational function, has failure modes that can be avoided with regular maintenance and has a failure probability that increases with time or use. Equipment that has random failures that are not maintenance-related, and that do not perform a critical function, should be disregarded in this scope.

The KAIZEN™ approach to implementing predictive maintenance contains four steps:

1. Selection of components and control parameters: it is crucial to start with critical assets to improve the functioning of this specific equipment. At this stage, there’s also the criteria definition, designed to prioritize equipment based on safety & environment, quality, availability, and process speed. The control parameters are also studied and defined in this particular step.

2. Definition of diagnostic methods and baseline values: equipment condition assessment can be done through periodic (offline) or continuous (online) monitoring of the equipment’s condition. This step aims to specify how to perform instrumentalized and non-destructive tests and inspections and define the baseline values. Most predictive inspections are performed while equipment is in service, thereby minimizing disruption of normal system operations.

3. Definition of suitable technologies: the predictive analysis utilizes various statistical and machine learning algorithms to provide recommendations and answers to questions related to what might happen in the future. Since it is a probabilistic method, the accuracy of the outcome depends on the data quality. There are different technologies to use, like computerized maintenance management systems, vibration analysis, remote visual inspection, acoustical analysis, infrared monitoring and analysis, oil analysis and model-based condition monitoring.

4. Predictive intervention: this step encompasses the design of the plan with all the information, such as which components are indicated for this approach, what are the control parameters for each piece of equipment, what are the reference values, what technologies are to be applied, and also what are the inspection points?

The main advantage of using this strategy is improving the operation of critical equipment, which will result in less need for corrective maintenance and generate savings in terms of time and money due to unplanned work avoidance. The continuous state of organization and control, which is the basis for preventive (periodic or predictive) maintenance, maximizes the availability and reliability of equipment and ensures processes at the lowest cost, allowing good decision-making for the management of assets in the long term.

Switching from reactive to predictive maintenance

Today, maintenance must adopt a system more focused on prevention and less on the reaction and resolution of malfunctions; this strategy must be implemented in a global way and must necessarily be integrated with production.

The implementation of a model based on Total Productive Maintenance principles, through the application of predictive and planned approaches, which will optimize spare parts stock management and reduce equipment downtime, while maximizing efficiency, is the most effective solution to optimize maintenance processes. This new paradigm can take the organization from a repair and fault management strategy to an integrated maintenance and production management one, focused on preventing equipment anomalies.

The ultimate goal of Predictive Maintenance is to perform maintenance at a scheduled point in time when the maintenance activity is most cost-effective, and before the equipment loses performance within a threshold, reducing maintenance costs, increasing equipment availability, equipment lifetime and safety.

Impact of predictive maintenance on the overall equipment effectiveness

By implementing predictive maintenance, teams will be able to gain insights into the need for maintenance before a significant downtime occurs – keeping equipment running. This makes the companies maintain not only high production time but also superior performance levels. This adoption intends to bring about an increase in the availability of resources, considered a key variable for the success of the organization, and for the OEE calculation.

The application of the predictive maintenance strategy will increase the organization’s overall OEE as it will allow preventive maintenance tasks to be carried out just before failures occur, drastically reducing both the planned stoppages of periodic inspections and the unplanned stoppages resulting from potential breakdowns.

Top challenges faced while implementing predictive maintenance

Typical maintenance challenges involve for instance the lack of resources, funding, or training. However, recently, (and following the same logic as other business areas), maintenance has faced a paradigm shift as digitalization and innovation bring new variables to the equation.

Due to the need to remain competitive, organizations cannot neglect this aspect, and the paradigm must evolve. More companies are focusing on predicting possible future defects and channelling less effort into solving challenges at the moment they arise.

To develop predictive maintenance strategies, Industry 4.0 and the application of digital tools can also be differentiating factors.

There are solutions like:

- Data analytics and all that can lead to predictive maintenance and conditioned-based maintenance

- Digital twins and simulation improve machine reliability right from the design phase

- Augmented reality increasing global remote expertise collaboration in maintenance interventions

- Maintenance 4.0: cyber-physical systems

- Real-time machine data availability (process and machine parameters)

Digital transformation and innovation can play a key role in maintenance activities and show special relevance in the implementation of the predictive maintenance strategy. Only organizations capable of embracing these methodologies and leveraging them will achieve the much-desired transition from the current paradigm of ‘solving’ to the vision of ‘preventing’.

See more on Process Manufacturing

Find out more about transformation in this sector

See more on Maintenance

Find out more about improving this business area